Concrete Repair Specialists

Di-Tech Restoration Inc.

Warehouse Concrete Floor Repairs

- Crack repair

- Epoxy repairs at grade beams & Pile cap jackhammer and epoxy to create flat floor

- Tripping hazards

Freezer Floor Repair

Using cold temperature appropriate material to repair floor cracks, deteriorated concrete, and sunken/heaving slabs

Anchors

Di-Tech Restoration supplies and installs mechanical and adhesive anchors for machine bases, equipment, structural members, etc.

Cement & Epoxy Grouting

Machine base grouting, contact grouting, column grouting.

Concrete Strengthening

- External Carbon Fiber Beam/Slab Reinforcing

Concrete Repair

- Crews jackhammer out all deteriorated or “unsound” concrete

- Sandblasting services to clean concrete and rebar to near white metal

- Deteriorated rebar added/ replaced

- Pour concrete to match existing

Traffic & Floor Coating Removal

- Large and small solutions for any project

- Scraping

- Grinding all completed with Hepa vacuums attached, for a dustless process

Expansion Joint Repair/ Replacement

- Cut and/or jackhammer out old expansion joints or steel angles

- Form and pour all necessary key ways for expansion joint system

- Sandblast to clean all surfaces

- Test fit and cut/rubber weld to size if needed

- Complete install using manufacturer materials

Soffit Slab & Beam Repairs

- Jackhammer deteriorated concrete using the latest in safety and breathing apparatus for our employees

- Sandblast rebar and concrete

- Form and pour using self-compacting concrete or pressure grout using non shrink materials

Heated Slabs & Toppings

- Remove existing slab or topping as required and concrete sounded below

- Patch existing structural slabs as required

- Sandblast surface for bonded topping or membranes

- Rebar and heat cable or tubing installed

- Place and finish as per spec

Cold Liquid Applied Waterproofing Membranes

- Remove existing slab or topping as required

- Entire surface sandblasted as per spec.

- All joints caulked using a multi component polyurethane sealant

- Membrane applied in stages as per manufacturer recommendation

- Final finish – concrete, paving stone, gravel, etc.

Epoxy/Urethane Traffic Coatings

- Repair all deteriorated concrete

- Shotblasted concrete surface and prepare edges as per spec

- All joints and vertical transitions caulked using 2 component polyurethane sealant

- Apply Primer

- Basecoat applied by squeegee then back rolled to achieve even mil thickness

- Topcoat (multi-layer depending on application) is squeegeed on, back rolled to even finish, aggregate is cast in as per spec and then back rolled to encapsulate it in the coating

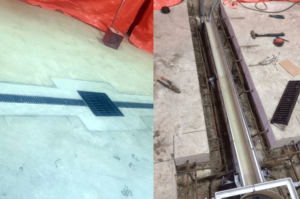

Drainage Trench Installation

- Sawcut and remove concrete

- Set drainage system and pit

- Cast new floor sloped to drain